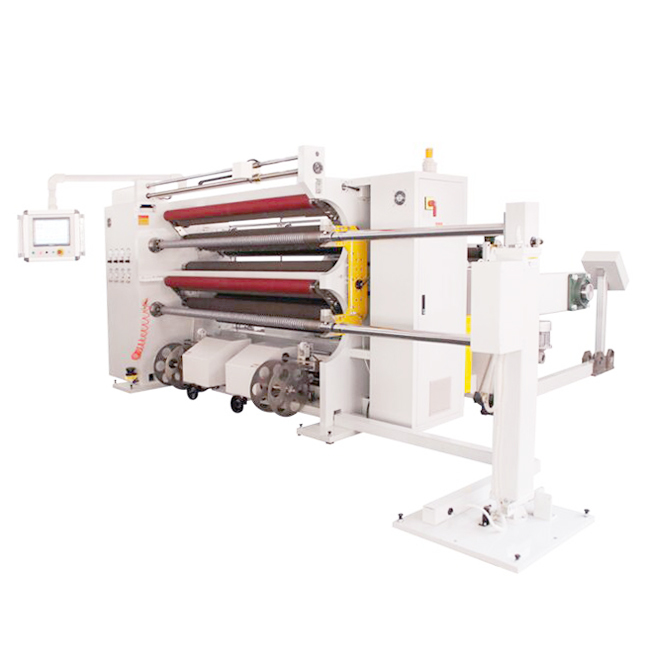

High Speed Paper Slitting Machine HN1600P

HN1600P is a professional Paper Slitting Machine, with air blade system, it can slit all kind of paper from 40gram to 500 gram paper. The max unwinding diameter can be 1500mm, the max rewinding diameter can be 1000mm, with 600m/min speed, it is a very cost effective paper slitting machine

If you have your own design, please contact us, there will have a professional customer service to communicate with you.

Don't have your files right now?No worries, Check out our art tips for more information.

If over 500pcs, mass production will start until pre-production sample has been approved.

Est. 7 days production

HN1600P BIG DIAMETER PAPER SLITTING MACHINE

APPLICATION

HN1600P big diameter rewinding slitter is specially design for large rolling materials, such as PET, BOPP, PE, paper sticker, paper, compound printing paper and so on. It is popularly used by slitting 40-450 gram paper. It is a very cost effective slitter in China.

BASIC SPECIFICATION

| 1 | SLITTING WIDTH | MAX1600MM | ||

| 2 | SLITTING THICKNESS | 50-450 GRAM | ||

| 3 | UNWIND DIA. | MAX1400MM | ||

| 4 | UNWIND CORE I.D. | 3 INCH OR 6 INCH AIR SHAFT OPTIONAL: SHAFTLESS | ||

| 5 | REWINDING DIA. | MAX1000MM | ||

| 6 | REWINDING WIDTH | MINI40MM | ||

| 7 | REWINDING CORE I.D | 3 INCH AIR SHAFT | ||

| 8 | SLITTING UNIT | SHEAR BLADE 10 SETS | ||

| 9 | MECHANICAL SPEED | MAX450M/MIN | ||

| 10 | WORKING SPEED | MAX350M/MIN | ||

| 11 | WELL THICKNESS: | 40MM | ||

| 12 | METER COUNTER: | METER COUNTER | ||

| 13 | WASTE EDGE UNIT: | AIR BLOWER | ||

| 14 | POWER SOURCE | 380V,3 PHASE,50Hz 21Kw | ||

| 15 | PNEUMATIC SOURCE | 0.8MPA | ||

| 16 | MACHINE SIZE (REF. ONLY): | 3400MM*2800MM*1700MM | ||

| 17 | FLOOR SPACE(REF.ONLY): | 3500MM*3000MM | ||

| 18 | N.W/G.W (REF. ONLY): | 3500/4000 | ||

| 19 | COLOR: | WHITE AND YELLOW |

FUNCTION DESCRIPITON

| A. | It does not need to input the material thickness, the proximity switch can inspect the unwinding diameter directly which near the transmission shaft. The machine can slow down according to the rest material, in this way, the worker can prepare for the next roller. | |||||||

| B. | Automatic unloading finished roll, easily for operation. | |||||||

| C. | Each rewinding shaft with 1 set of 7.5KW servo motor to drive the air shaft. The tension decided by the roll diameter. PLC controls SMC electric automatically to make all the sheet same thickness when do the multiple slitting. Because of the press roller, all the reels end face is smooth. it has the choice of pneumatic press roller and self-weight press roller. The screw type rewinding way can control the degree of the tightness of the finished products. With the increasing of the rewinding diameter, the servo motor speed goes down to extend the life of the air shaft. | |||||||

GUARANTEE AND SERVICE

| 1 | ONE YEAR GURANTEE FOR THE KEY PARTS OF THE MACHINE, THE PARTS ARE AS FOLLOWING: | |||

| MOTOR, PLC, TOUCH SCREEN,MAGNETIC POWDER CLUTCH | ||||

| 2 | MACHINE INSTALLING AND WORKER TRAINNING SERVICE. | |||

| A. ENGINEER AVAILABEL ON YOUR FACTORY TRAINNING AND INSTALLING | ||||

Related Products |

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian Afrikaans

Afrikaans Albanian

Albanian Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque