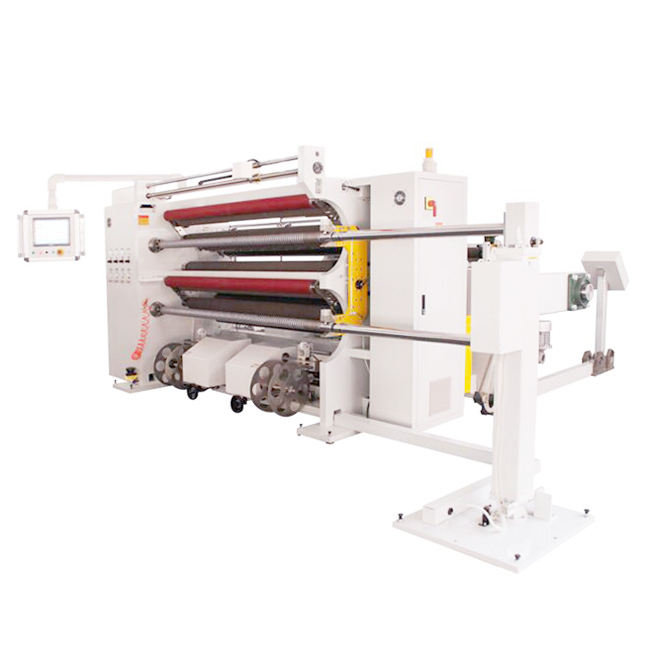

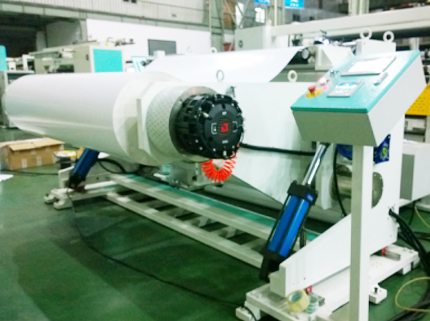

HN2000-F Slitter Rewinder For Plastic Film Paper Foils Labels

HN2000-F Slitter Rewinder For Plastic Film,Paper,Foils,Labels is a high speed 2000mm slitter rewinder. The max speed can be 600m/min, it can slit Primary Film( BOPP, BOPET, BOPA, CPP, HDPE, OPP, PVC, PET, PE, LDPE...),Laminates(Film To Foil, Film To Film, Film To Paper...), Various Foil( 12-200um),Non-Woven Fabric And other Material from 12-200 micrometer. If you need more information, please contact at [email protected];

If you have your own design, please contact us, there will have a professional customer service to communicate with you.

Don't have your files right now?No worries, Check out our art tips for more information.

If over 500pcs, mass production will start until pre-production sample has been approved.

Est. 7 days production

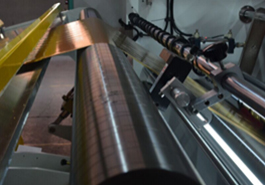

A:12-180um HOT STAMPING FOIL,COLDING FOIL,HOLOGRAPHIC FOILS,METALIZED FOIL and so on

B:12-180um PRIMARY FILM (BOPP,PVC,LDPE,PET,SINGLE SILICON FILM and so on)

C:12-180um LAMINATES (FILM to FILM,FILM TO FOIL,FILM TO PAPER and so on)

D:Non-Woven FABRIC

E:40-80gram PAPER/LABEL/ADHESIVE LABEL

| SLITTING WIDTH | 300mm-2000MM |

| SLITTING THICKNESS | 12-180UM |

| UNWIND DIA | MAX1200MM |

| UNWIND CORE I.D | SHAFTLESS 3 INCH AND 6 INCH |

| REWINDING DIA | MAX 650MM |

| REWINDING WIDTH | MINI 30MM |

| REWINDING CORE I.D | 3 INCH SLIPPING AIR SHAFT |

| SLITTING UNIT | RAZOR BLADE AND SHEAR BLADE 2 BLADE SYSTEM |

| MECHANICAL SPEED | MAX450M/MIN |

| WORKING SPEED | MAX400M/MIN |

| MACHINE FRAME THICKNESS | 40MM |

| METER COUNTER | METER COUNTER |

| WASTE EDGE UNIT | AIR BLOWER |

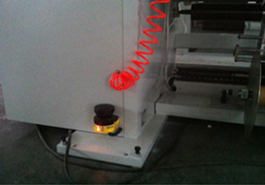

| POWER SOURCE | 380V,3 PHASE 4 WIRES,50Hz |

| PNEUMATIC SOURCE | 0.8MPA |

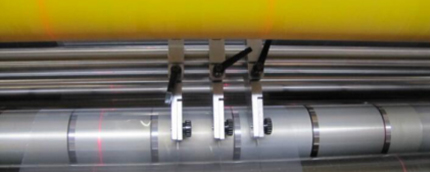

| LASER POSITIONING | 10 PCS |

| POWER | 18KW |

| N.W/G.W (REF. ONLY) | 8000KGS |

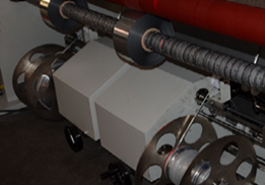

1: 2 pcs 3 inch Slipping Air Shafts;

2: Full width pressing rollers by air control to ensure the finished roll surface keep smooth;

3: Manual laser core position units help to set paper/plastic cores easily and quickly, begin next slit run with very short downtime.

4: Automatic tension control to ensure the rewinding tension stable;

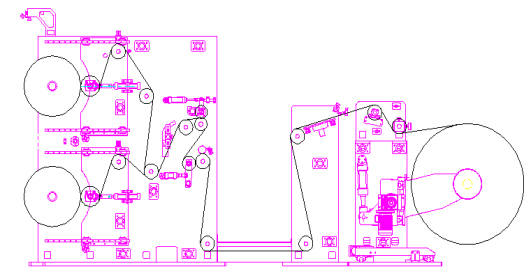

5: 2 rewinding motors to drive up and down rewinding shaft, to ensure the rewinding stable and it can rewinding different length for up and down shaft;

6: Automatically tension control, by setting the mateiral thickness, the slitter can automatically sense the diameter an control the rewinding tension automaticlly;

1: Manual finished roll unloading tree to help unload finished rolls conveniently;

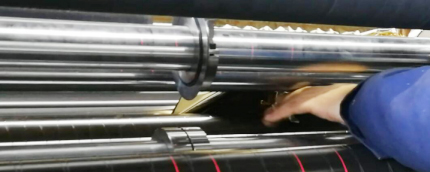

1: Razor blade slit + Shear blade slit. Razor and Shear blade system changes by removing the razor blade shaft out and put on the up shear blade shaft. Down blade system do not need to change.

2: Razor blade setting easily setting by wrench losing and fixing, very quick and easy;

3: Shear Blade system: up blade is using self-locking blade, it can easily move and fix by the screw; down blade setting by air shaft system, lose and fix the blade through the air deflating and filling, saves 50% time than the traditional way;

1: Air Brake with load cell close loop system for unwind tension control

2: 3 inch and 6 inch shaftless uwinding system, easily change the jumbo roll

3: Hydraulic lifting system to help the operator loading the jumbo roll max. 1 ton from floor;(Optional)

4: Material splice table, easy change and guarantee edge consistency

5: EPC ultrasonic edge guider to avoid the influnce from shinning materia which reflect light back

6: Splice tabel to help operator make joint easily when change jumbo roll

1: Trim sytem: lower noise air blower to ensure the stability of blowe the trim material out;

1: 100% Test and Check Before Shipment

2: Detailed Instruction Manual

3: One Year Guarantee for All Key Parts

4: Installing and Operator Training Service Provided

5: Whole-Life Free Technical Support

6: Regular On-Site Routine Inspection

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian Afrikaans

Afrikaans Albanian

Albanian Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque